What are the usual considerations for the thickness of laser wire mesh with red glue solder paste?

The thickness of the paste wire mesh is considered by the precision of the welding layer of electronic components. High precision electronic components are made of thin steel sheet, and large welding layer components are made of thick steel sheet. The thickness of solder paste mesh is usually between 0.08-0.18mm, and that of red glue mesh is between 0.15-0.3mm. Which components are high precision?

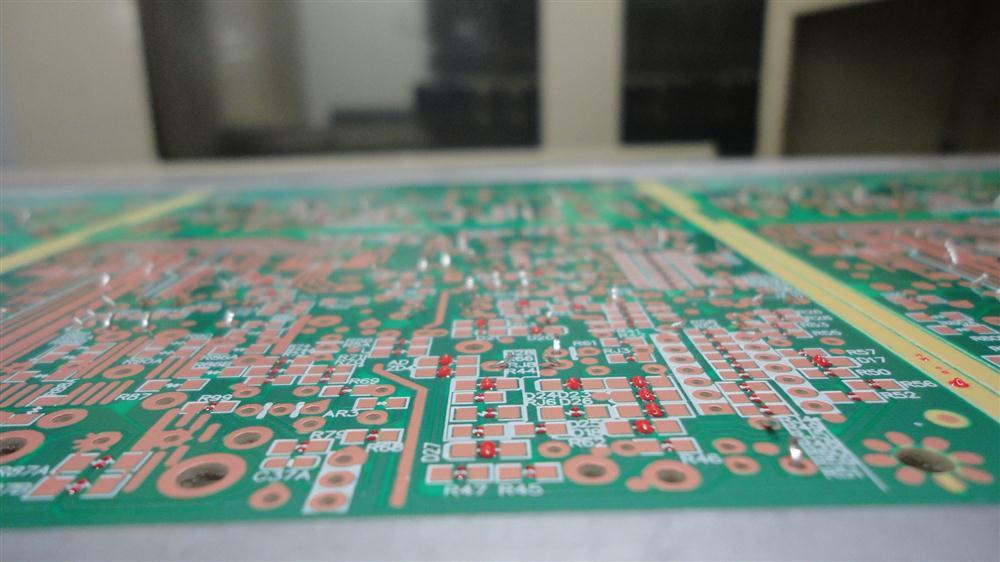

Generally, 0201 components can use 0.08mm thin steel plate, 0402 components can use 0.1mm thin steel plate, 0603 components can use 0.12mm thin steel plate... It is based on the size of resistance and capacitance components to judge, then a PCB board is not only such, but also IC, BGA and other components, in this case, it must be based on the minimum IC interval to judge the thickness of wire mesh, Otherwise, too thin will be less tin, too thick will be more tin. The thickness of steel wire mesh is one of the most important factors affecting the quality of steel wire mesh.